Speakers

TBA

American Industrial Partners

American Industrial Partners

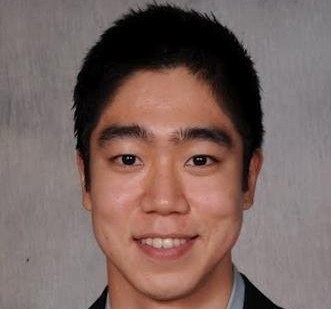

Brian

Albright

Panel 3: AM and Industrial-Scale Automation

Brian is the Editorial Director of Digital Engineering / DE247 at Peerless Media. Visit us at digitalengineering247.com

Amy

Alexander

Panel 3: Enablers to Scale AM in Healthcare

Amy Alexander, MS, is Unit Head of Mechanical Development and Applied Computational Engineering within Mayo Clinic’s Division of Engineering (DOE). In this role, she bridges the medical device development and additive manufacturing capabilities of the DOE with the needs of the clinical practice. Amy is past Chair of the SME Medical Additive Manufacturing Technical Advisory Team and a long-standing member of the Radiological Society of North America’s 3D Special Interest Group. Amy is a frequent co-author of medical 3D printing peer-reviewed papers, and long-term reviewer for Springer’s 3D Printing in Medicine Journal. She serves as a member of Biomedical Engineering Industrial Advisory Committees for multiple universities and is a frequent lecturer on medical 3D Printing. In 2019, she was recognized as one of 14 international recipients of the SME Outstanding Young Manufacturing Engineer (OYME) award. She holds certificates in Additive Manufacturing from MIT and SME. Amy holds a Bachelor of Science in Biomedical Engineering and a Master of Science in Engineering Management from MSOE.

David

Alexander

Panel 2: The Industrialization of Additive for Aerospace

David Alexander has been with SAE International and its affiliates for 20 years and is currently located in Detroit, Michigan, USA, having previously been based in London. In the role of Senior Director of Standards, Alexander is responsible for the coordination and collaboration of SAE’s standards programs and constituents across diverse mobility sectors including aerospace, automotive and commercial vehicle. He is also responsible globally for the strategy and operations of the SAE Aerospace Standards program – including a growing portfolio in Additive Manufacturing. This includes the SAE leadership for the SAE Executive Standards Committee and SAE Aerospace Council and stakeholder integration of standards through the SAE Group portfolio.

Supported by SAE staff in London, Brussels, Shanghai and across the US, program activities include relationships with industry, associations, regulatory authorities and government stakeholders around the world and strategy for standardization in areas as diverse as artificial intelligence, predictive maintenance, hydrogen & sustainable fuels, electrification, additive manufacturing, human factors and quality.

Prior to joining the SAE Aerospace Standards operation, David worked on the Nadcap accreditation programme through SAE’s affiliate organisation PRI, and he holds a BA (Hons) degree from the University of Manchester.

Roger

Antúnez

Talk 1: Enabling the Manufacturing of Parts that the World Needs Through Material Processing Technologies & Chemistry

Panel 6: Polymer AM Materials

Roger Antúnez is the Founder and CEO of Supernova. With its breakthrough materials, customers can produce parts that achieve properties comparable to molded plastics such as EPDM, glass-filled PA6, or PP, enabling scalable and reliable production batches. The company is pushing the boundaries of photopolymers by utilizing high molecular weight oligomers, which have viscosities that can only be processed using Supernova’s proprietary Viscous Lithography Manufacturing (VLM) technology. Headquartered in Austin, TX, with a branch in Barcelona, Spain, Supernova has assembled one of the strongest teams in the industry and is poised to become a leading player in the next decade.

Prior to founding Supernova, Roger served as General Manager at BCN3D, where he was instrumental in transforming the company into a global leader in 3D printing with its Independent Dual Extrusion (IDEX) technology. During his tenure, he led the company’s global commercial expansion and played a pivotal role in the acquisition of Astroprint to completing the company’s product. He continues to serve as a board member at BCN3D.

Roger’s experience in additive manufacturing, combined with his leadership at Supernova, highlights his deep expertise in advancing material capabilities and scaling AM technologies for industrial applications.

Ben

Arnold

Panel 1: The Polymer Toolbelt

Ben Arnold is the Founder of Additive Advocates, a consultancy focused on growth strategies for Additive Manufacturing businesses. Ben has worked in the AM industry since 2006 in Sales leadership roles with OEMs bringing new technology platforms to market. He has experience in polymers, metals, and ceramic modalities.

Ben holds BS in Mechanical Engineering from WPI and MBA from Northeastern University’s High Technology program. He was recognized for his work in the Additive Manufacturing industry with a DINO award from the AM User Group.

Jason

Ball

Panel 1: Specialist Services

Jason Ball is Vice-President and General Manager of Burloak Technologies as of December 2021. In his role, he is responsible for leading the Company’s global operations and further accelerating the adoption of Additive Manufacturing (AM) technologies across various industries. Jason began his career at GE in 2000, and held several increasingly complex leadership roles in engineering, quality, and product management in GE divisions including GE Power and GE Additive. In 2018, Mr. Ball led the development of GE Additive’s ATLAS (Additive Technology Large Area System) Program.Following his time at GE Additive, Mr. Ball joined SLM Solutions, a manufacturer of industrial 3D metal printing machines, where he was first head of product management at the company’s headquarters in Germany, then General Manager of its Canadian business. Mr. Ball is a licensed engineer and holds a Bachelor of Applied Science in Mechanical Engineering degree from the University of Waterloo.

John

Barnes

CEO, Metal Powder Works

Presentation: Strategies for Success

Panel 5: Metal AM Materials

John has a 25+ year career in product development and aerospace with Honeywell, Lockheed Martin Skunk Works™, Australia’s CSIRO, and Arconic (formerly Alcoa and RTI International Metals). He’s been involved in metal additive manufacturing throughout this career beginning in the late 1990s where he was part of the Sandia National Labs LENS™ CRADA. Since then, he has been in and around AM working both technical and business cases for implementation and development efforts in materials, powders, processing, and printing to mature the technology for applications. John is recognized internationally for contributions to additive manufacturing, product development, and leadership in engineering. His groups boast world firsts in medical, therapeutic, and aerospace additive manufacturing. John is a Materials Engineer by background but has developed expertise in manufacturing, airframe structures, gas turbines and low observables. He is currently an Adjunct Professor at RMIT University, and an Adjunct Senior Research Fellow at Monash University, both in Melbourne, Australia. In 2014, he was Purdue University’s Materials Engineer of the Year, and in 2017, he was invited to join the Additive Manufacturing Technical Community as a SME Advisor based upon active industry contributions, reputation, and personal commitment to expand the use of additive manufacturing.

Mark

Benedict

Panel 2: The Industrialization of Additive for Aerospace

Dr. Mark Benedict, a member of the scientific and professional cadre of senior executives, is the Senior Scientist for Convergent Digital Manufacturing, Materials and Manufacturing Directorate, Air Force Research Laboratory, Wright-Patterson AFB, Ohio. He serves as the principal scientific authority and independent researcher in the research, development, adaptation, and application of advanced manufacturing and is a recognized expert on additive manufacturing process modeling, machine development, data management, and airworthiness qualification/certification. In his prior role as America Makes Chief Technical Advisor he was integral to the planning, requirements definition, selection, and execution of the $446M technical portfolio that America Makes has in the area of convergent manufacturing over the last decade.

Tyler

Benster

Panel 8: Shark Bites: VCs Discuss Why They Do or Don't Invest in 3DP/AM

Tyler is a Neuroscience PhD student at Stanford University and a General Partner at Asimov Ventures. At Asimov Ventures, Tyler has invested in more than 20 startups across 3D printing, robotics, and frontier tech, including Additive Orthopaedics, Sadako, Ghost Robotics, and Kiwi. As a writer and analyst, he has been featured in Bloomberg, TechCrunch, GigaOm, Wohlers Report, and Computer World, and has chaired or keynoted at more than twenty international conferences, including Inside 3D Printing and RoboUniverse. His scientific work has been published in Cell and Scientific Reports. Tyler received a B.S. in Applied Mathematics and Economics at Brown University and grew up on Mercer Island in Washington State.

Kate

Black

Panel 3: Sustainability: Powering the Bottom Line

Professor Kate Black is the CEO of Atomik AM, a pioneering company transforming advanced manufacturing through sustainable and innovative solutions. Under her leadership, Atomik AM combines advanced chemistry with engineering to help manufacturers reduce costs, waste, and environmental impact. Kate is also a Professor of Manufacturing at the University of Liverpool UK, where she contributes to cutting-edge research and teaching in additive manufacturing. A Fellow of the Royal Academy of Engineering, Kate is widely recognised for her contributions to the field and her dedication to driving sustainable change in the industry.

Stefanus

Bosch

Talk 1: Integrate to Scale - How Additive Manufacturing Works for the BMW Group

Stefanus is responsible for the additive manufacturing research and development team, as well as planning and digitalization, at BMW Group’s Additive Manufacturing Campus. His team scouts and industrializes new AM technologies and develops the software tools needed to manage BMW’s AM production network. Previously, he was responsible for the design for AM team, pushing world’s first AM use-cases for all BMW brands across a wide range of applications.

Before joining BMW, Stefanus worked on metal additive manufacturing and generative design at Airbus APWorks, where he played a pioneering role in the development of the Light Rider, the first-ever 3D-printed electric motorcycle.

Stefanus holds a Master’s degree from the Technical University of Munich. He completed his studies in engineering science at the Munich School of Engineering and at Nanyang Technical University in Singapore.

Stefanie

Brickwede

Keynote: The Beauty of an Empty Warehouse: Saving Millions with AM in Rail

As Managing Director, Stefanie Brickwede passionately set up the international leading network “Mobility goes Additive” in 2016 with the aim of pushing industrial 3D printing into series production. 2019 a second branch was launched: „Medical goes Additive“ assists Hospitals, companies and institutions throughout the medical sector to extent the use of Additive Manufacturing. Now, MGA has more than 140 members active in close to 20 working and focus groups with more than 70 meetings a year.

After graduating as an economist from the Technical University of Hanover, she started her career in the mobility sector and has since held various management and project management positions at the Deutsche Bahn AG. Since 2015, Stefanie also heads the corporate project 3D Printing at the DB and is responsible for the successful introduction of Additive Manufacturing throughout the DB group. This gives her a deep understanding of the opportunities and challenges users have to face.

In addition, Ms. Brickwede is the initiator of the “Women in AM” network and actively promotes women in the AM industry.

Louis-Philippe

Broze

Panel 4: Policy for AM Healthcare

Louis-Philippe Broze, aged 29, stands as the co-founder of Spentys, a Brussels-based startup established in 2018. Spentys specializes in empowering orthopedic technicians and various healthcare providers by offering them the capability to perform 3D scanning, 3D modeling, and 3D printing of personalized prosthetics and orthotics for individual patients.

Operating across more than 20 countries worldwide, with a dedicated branch in the USA, Spentys has garnered significant attention in the industry. The company has successfully secured over $7 million in funding from investors and its groundbreaking technology has positively impacted the lives of over 20,000 patients.

In recognition of his outstanding contributions to science and healthcare, Louis-Philippe & his co-founder Florian De Boeck earned a prestigious nomination as one of Forbes Magazine’s “30 Under 30 – Europe – Science & Healthcare” in 2023. Demonstrating a steadfast belief in the power of entrepreneurship to drive societal change, Louis-Philippe is committed to nurturing and fostering impactful initiatives.

Lars

Brubaker

Panel 6: Polymer AM Materials

Lars Brubaker is the CEO of MatterHackers, a leading company in the 3D printing industry. With a passion for innovation and technology, Lars has been at the forefront of several successful ventures. Before founding MatterHackers, he co-founded Reflexive Entertainment, a video game company known for its creativity and high-quality games. Under his leadership, Reflexive Entertainment developed and published numerous popular titles, earning a strong reputation in the gaming community. In 2008, Reflexive Entertainment was acquired by Amazon, where Lars continued to contribute to the gaming and digital content landscape. At MatterHackers, Lars leverages his extensive experience in technology and business to drive the company’s mission of making 3D printing accessible and user-friendly for everyone. His visionary leadership continues to inspire innovation and growth in the 3D printing industry.

Mark

Burnham

Panel 4: Policy for AM Healthcare

Mark Burnham serves as the Director of Policy for the Additive Manufacturing Coalition (www.addmfgcoalition.org). He has more than 20 years of experience representing universities, associations and technology focused entities in Washington, D.C. Mark has served in different capacities over the years, sometimes as an in-house advocate and sometimes as an outside lobbyist to various entities including Caltech, Fermilab, UCAR/NCAR, Oakland University, University of Michigan and Michigan State University where he spent 11 years, eventually serving as MSU’s Vice President for Government Affairs.

During his career, Mark has worked with every federal science related agencies as well as with most national higher education associations. Some of the biggest projects he has worked on include helping get funding from Congress for two Mars Rovers, assisted with the establishment of the IACMI facility in Detroit, and approval for, and state and federal funding of the Facility for Rare Isotope Beams (FRIB), a $730 million rare isotope accelerator which will commence full operations later this year (2022).

Mark began his career working for Congresswoman Mary Kaptur (D-OH), the current Chair of the Energy and Water Appropriations Subcommittee where he served on her personal staff as the liaison to the committee on NASA, NSF and Veterans Affairs appropriations.

Mark holds a Bachelor’s in Political Science from the University of Michigan and a Juris Doctor from Boston College Law School.

Stephen

Butkow

Panel 7: M&A and Capital Markets

Stephen joined Stifel in 2017 and is a Managing Director and Co-Head of the Electronics & Industrial Technology team within Stifel’s Global Technology Group. He has over 20 years of investment banking experience and specializes in advising clients within the 3D printing, digital manufacturing, factory, warehouse automation, digital and packaging print, technology reseller, integration, and distribution sectors.

Prior to joining Stifel, he worked at Citigroup as an investment banker in both the Global Industrial Group, Global Transportation Group, and as a workout specialist in Citigroup’s North American Substandard & Non-Performing Loan Workout Group. Stephen began his career at Arthur Andersen in corporate restructuring.

Joe

Calmese

The Power of Investment: Accelerating AM with Private Equity

Joseph Calmese is the President & Chief Executive Officer at ADDMAN, where he leverages over 15 years of experience in strategic leadership, business expansion, and innovation. Since 2021, he has guided the company’s three specialized manufacturing groups, focusing on pioneering advances in American manufacturing.

Joseph is deeply committed to enhancing customer satisfaction, drawing on his experience in advanced manufacturing, operational improvement, and manufacturing automation to deliver exceptional value to ADDMAN’s customer partners. Based at ADDMAN’s location in St. Louis, MO, Calmese holds a Bachelor of Science in Physics from Illinois College and an MBA from Washington University in St. Louis.

Daghan

Cam

Talk 2: Robots vs Humans: How Far Can Automation Take Us in Manufacturing?

Daghan Cam is the co-founder and CEO of Ai Build, a London based software company founded in 2015. Ai Build provides web based additive manufacturing software for robotic and gantry 3D printing systems used by tier 1 global enterprises across Aerospace, Automotive, Energy, Construction and Marine sectors in the production of 3D printed parts and R&D prototyping. Ai Build prides itself on rapid innovation that enables efficient automated manufacturing in an efficient, repeatable, autonomous and scalable manner.

Michael

Cao

Panel 1: The Polymer Toolbelt

Michael Cao founded IC3D in 2012 while working at Honda R&D. He began his 13 year tenure at Honda focusing primarily on polymer part development and ended as project leader on the flagship Acura NSX supercar.

At IC3D, Michael and his team are focused on developing the next generation microfactory that aims to improve sustainability and enhance production by utilizing polymer waste streams. His work includes funded research and collaborations with government entities such as the US Army, Air Force, Marine Corps, Office of the Under Secretary of Defense – Research and Engineering, NIST, and the Department of Energy, primarily in polymer materials and process research. Michael holds a BA in Mechanical Engineering from the University of Oklahoma.

Jenny

Chen

Panel 3: Enablers to Scale AM in Healthcare

Jenny Chen, MD, is the Founder and CEO of 3DHEALS, a company focusing on educating, connecting, and discovering innovators and entrepreneurs in bioprinting, regenerative medicine, and healthcare applications using 3D technologies. Dr. Chen serves as a startup mentor and advisor to 3D technology startups. She created the Pitch3D program that connects early-stage startups to various fundraising strategies and directly to 35+ institutional investors in healthcare 3D printing and bioprinting. Her interests lie in automated biology, patient-specific medicine, and biofabrication, and she has a vision of a decentralized and personalized healthcare delivery system for our near future.

Andrew

Cunningham

Panel 1: AM for Mobility

Andrew Cunningham is a Senior Application Engineer at Nikon SLM Solutions, where he leads global technical development for the automotive and motorsports industries. In this role, Andrew drives innovation in additive manufacturing (AM) by enabling cutting-edge solutions for high-performance applications.

Previously, Andrew spearheaded General Motors’ motorsports additive manufacturing initiative, delivering over 120 race-proven applications that pushed the boundaries of performance and reliability on the track.

Before joining GM, Andrew rotated through several roles at Ford Performance, where he contributed to the development of iconic vehicles like the Mustang GT500, F-150 Raptor, and NASCAR Cup Mustang.

Andrew holds an M.Eng. in Advanced Manufacturing and Design from MIT and a B.S. in Mechanical Engineering from Cal Poly San Luis Obispo.

Andy

Davis

Panel 6: Bridging the Public-Private Gap

Andy Davis is a respected leader in the Defense advanced manufacturing and industrial base community, known for his ability to catalyze diverse groups to collaborate for a common cause. He spent 19 years within the Department of Defense, most recently as the Deputy Director and Chief Technology Officer of the Industrial Base Analysis and Sustainment (IBAS) Program, where he led the organizational design, program planning and management, strategic planning, technical assessments, and the expansion of Program acquisition platforms. Prior to that, Andy worked for the U.S. Army Combat Capabilities Development Command (DEVCOM), including a role as the Army’s Global Technology Advisor to the United Kingdom, Israel and South Africa; he lived in the U.K. with his family and focused on connecting industry, academia and allied Ministries of Defense with U.S. Army researchers. Andy also led the Army’s Manufacturing Technology (ManTech) Program, where he helped launch the Manufacturing USA Institutes, led the Army and DoD in first-of-their-kind AM technology roadmaps, created the Army’s AM community of practice, helped draft the Army’s AM campaign plan, and led the Joint Defense Manufacturing Technology Panel (JDMTP) in establishing a strategic framework to standardize cross-DOD collaboration. Prior to this, Andy held a variety of Army mechanical engineering positions, primarily focused on electro-mechanical design and prototyping. Andy received his bachelor’s and master’s degrees in Mechanical Engineering from Grove City College and Johns Hopkins University, respectively. Andy loves spending time adventuring with his family, is an avid outdoorsman, enjoys demolition derbies and is learning to master the art of smoking meats.

Danny

Davis

The Power of Investment: Accelerating AM with Private Equity

Danny Davis joined American Industrial Partners in 2008, bringing experience from his previous roles at Intel Corporation and Cisco Systems, where he held key positions in process engineering and program management. He holds a Bachelor of Science in Mechanical Engineering, graduating magna cum laude from the University of Michigan. Danny also earned a Master of Science in Mechanical Engineering from the Massachusetts Institute of Technology (MIT), followed by an MBA from MIT’s Sloan School of Management. He has been a member of the ADDMAN Board of Directors since the company’s founding in 2020.

Francesco

De Stefano

Talk 3: Automation & Robotic 3D Printing

Francesco is Co-Founder and CEO of Caracol, is an entrepreneur with significant international exposure, an extensive background in Management and Strategy, a deep knowledge of industrial goods sectors and Industry 4.0 technologies. After earning a bachelor’s in business administration and Management at Bocconi University, he earned a Master of Science in Management at London Business School. After short internship experiences in Finance & M&A, Francesco joined the Boston Consulting Group team in Milan where he worked for about 3 years on projects across Germany, Japan, UK, Turkey, Greece and Italy. During this time, he consolidated and deepened his Strategy and Operations capabilities, working for clients in Industrial Goods, with a focus on Automotive and Aerospace. Furthermore, he worked closely with major International Automotive and Aerospace groups to roll-out Industry 4.0 technologies (e.g., Additive Manufacturing) across their production lines. He mastered his managerial skills by completing an MBA at Columbia Business School in New York. Francesco and his co-founders founded Caracol in 2017, and he has been leading the team, its operations, fundraising and growth. He has been selected as Endeavor entrepreneur for the Elevator program in 2022.

Brigitte

de Vet-Veithen

Panel 3: Enablers to Scale AM in Healthcare

Panel 5: CEO Roundtable

Keynote: From Dreams to Deliverables – When Innovation Meets Reality

Brigitte de Vet-Veithen is CEO Elect at Materialise and a member of the Executive Committee. Effective on January 1, 2024, she will succeed Fried Vancraen as the company’s CEO, and will also become President of the Materialise Executive Committee. Brigitte joined Materialise in 2016 and is an accomplished business leader with over 20 years of experience across multiple industries.

Previously, she led the company’s Medical business and strategic projects running across all businesses as Executive Vice President of Materialise Medical, which develops software and 3D printing solutions that help improve patient outcomes. Under her leadership, the medical segment grew to become the company’s fastest-growing and most profitable business segment.

Prior to joining Materialise Brigitte held various management, sales, R&D and marketing positions at Johnson & Johnson, ultimately serving as General Manager for Cordis in Germany and VP EMEA for Cordis Neurovascular. She led several companies through growth and transformation, including in her role as CEO of Acertys Group, where she drove a significant effort to improve operational efficiencies, strengthen the technology portfolio, and create growth.

Brigitte holds an MBA from INSEAD and a BA with a major in Engineering from HEC Liege.

James

DeMuth

Panel 7: A Founder’s Journey: Fundraising for Scaling Applied 3DP

James holds an MS in Mechanical Engineering from Stanford University with a focus on energy systems and high-temperature gas dynamics, and a BS degree in Mechanical Engineering from Santa Clara University. He has co-authored 83 patents and 13 academic publications in the fields of additive manufacturing and power generation.

Prior to founding Seurat, James was at Lawrence Livermore National Laboratory where he worked on the Laser Inertial Fusion Energy project, and co-invented and developed the core of Seurat’s breakthrough technology in Additive Manufacturing.

Phil

DeSimone

Panel 1: The Polymer Toolbelt

Panel 5: CEO Roundtable

Phil is a member of the Office of the CEO. He was part of the founding team at Carbon in 2013, and most recently the Chief Product and Business Development officer responsible for Carbon’s product strategy and strategic partnerships. Most recently, Phil led the go-to-market strategy and managed Carbon’s most strategic partnerships and customer relationships. Prior to Carbon, Phil co-founded and was the VP of Business Development at Buystand, an ecommerce company. Phil received his BA in business and econometrics from Ursinus College.

Bryan

Dow

Panel 7: M&A and Capital Markets

Bryan Dow is a Managing Director in Stifel’s Global Technology Group where he Co-Leads the Electronics and Industrial Technologies Investment Banking practice. Bryan has over 17 years of Investment Banking experience specializing in Mergers & Acquisitions, Private Equity and Equity Capital Markets for disruptive businesses in advanced manufacturing, industrial software, IoT, and emerging technologies, such as 3D printing and drones. Bryan joined Stifel through its 2019 acquisition of Mooreland Partners where he was a Partner. Prior to joining Mooreland in 2013, Bryan was Head of the Clean Energy and Industrial Technology Investment Banking Group at ThinkEquity, where he advised clients on a range of transactions. Previously, he was also a member of the Technology Investment Banking Group at Needham & Company. Bryan earned a B.S. in Finance and Management Information Systems from the Leavey School of Business, Santa Clara University.

Matthew

Draper

Panel 5: Metal AM Materials

Dr. Draper is currently the Technical Director for Metallurgy and Manufacturing for the Innovation Capability and Modernization (ICAM) Office in the Office of the Deputy Assistant Secretary of Defense for Industrial Base Resilience; on detail from the US Navy.

In his current assignment Dr. Draper overseas an investment portfolio in casting, forging, and industrial metals production covering initiatives in infrastructure, workforce, automation, and alloy and process development that supports the Department of Defense (DoD) implementing Executive Action 14017. Matt is also working with the ICAM team on indigenous manufacturing and repair capability in the INDOPACOM Theater, and on DoD wide Advanced Manufacturing.

He currently sits on the Joint Defense Manufacturing Technology Panel (JDMTP) – Metals Subcommittee, The Technical Cooperation Program (TTCP) – Materials and Processing Technology Group Technical Panel as the United States National Lead, and the Steel Founders Society of America (SFSA) High Alloy Research Committee.

At his home command, Dr. Draper is the Principal for Alloy Development and Processing Technology at the Naval Surface Warfare Center – Carderock Division. Prior to joining the government Matt was the head of Materials Development at General Dynamics Electric Boat working on design of the COLUMBIA and VIRGINIA Payload Module and preceding that a process metallurgist at Scot Forge. Dr. Draper has a BS from Northwestern University (Olson Group) and a PhD from the University of Maryland (Ankem Group); both in Materials Engineering.

Scott

Dunham

AM Mid-Decade: Market Data

Presentation of AM Research Materials Forecasts

Panel 4: Market Forecasts

Foster

Ferguson

Panel 6: Bridging the Public-Private Gap

Foster joined Stratasys in 2019, where he focused on cultivating strategic partnerships and driving growth in the Government and Aerospace businesses. Prior to this, he served over 20 years in the Marine Corps, specializing in supply chain management and maintenance repair operations. His final role was Commanding Officer of the 1st Maintenance Battalion, overseeing 1,100 Marines and Sailors. Under his leadership, the unit was honored with the DoD Maintenance Unit of the Year award for two consecutive years.

As Vice President of Industrial Business, Foster is responsible for developing strategic partnerships and advancing manufacturing capabilities for market leading clients seeking to revolutionize their production and supply chain models.

Foster holds a Bachelor of Science degree from The Citadel, and a Master of Science in Supply Chain Management from the University of San Diego.

Ben

Ferrar

Talk 2: Is the AM Industry Ready for Closed-Loop Control?

Ben Ferrar is the Chairman of the Board and Chief Operating Officer at Phase3D, where he leads the commercialization of advanced quality assurance technologies using Fringe Projection to ensure superior part quality in additive manufacturing.

With 17 years of experience, Ben previously served as Vice President and General Manager at Carpenter Additive, enhancing the company’s global leadership in additive manufacturing solutions.

As Chief Operating Officer at LPW Technology, he drove sustainable growth and led investment strategies for a £20 million digital factory. Additionally, Ben has been a Strategic Advisor for 3DP4ME since 2020 and contributed to engineering education as an Industrial Liaison Board member at the University of Liverpool.

His expertise in corporate finance, board governance, and the industrialization of additive manufacturing technologies underpins Phase3D’s mission to provide trusted, high-performance solutions to the industry.

Marc

Fette

Panel 2: The Industrialization of Additive for Aerospace

Marc Fette is a distinguished professional holding key roles in the aerospace and manufacturing sectors. As the CEO of Composite Technology Center CTC GmbH, an AIRBUS Company, he oversees innovative developments in composite technology. Marc also serves as the Chairman of the VDI Advisory Board for Aerospace Technology, contributing to the advancement of the aerospace industry. Additionally, he holds the position of Chairman of the Board at CU NORD (Composites United e.V.) and plays a pivotal role as the Group Leader for Additive Manufacturing & Lightweight Construction at the Manufacturing Technology Laboratory, Helmut Schmidt University Hamburg.

Michael

Fuller

Panel 4: Applications

Michael’s career was launched off the back of his boyhood dream of designing racing cars. In 1999 he migrated to Europe as a Design Engineer, and over 15 years he held various design engineering and management roles in motorsport organisations competing in series as varied as the World Endurance Championship, World Rally Championship, and the Formula 1 World Championship. As an early adaptor of Additive Manufacturing (AM) in the motorsport industry he was acutely aware of the opportunities available to enhance performance.

After returning to Australia, he pursued a design idea on an AM heat exchanger that proved to have ground-breaking performance potential and launched Conflux soon thereafter. Conflux has now grown into a world leading organisation that combines specialisations in heat transfer and additive manufacturing.

Ric

Fulop

Panel 2: The Metal Toolbelt

Ric Fulop is a tech entrepreneur, manufacturing and power systems expert. He founded and is CEO of Desktop Metal, a manufacturer of 3D printers focused on mass production being acquired by Nano Dimension. Fulop is also co-founder and Chairman of Lumafield, one of the largest producers of industrial CT systems. He’s worked on technology used to make Tesla gigacasting molds, single crystal jet engine parts, structural components in P&W and Rolls Royce jet engines, parts for Formula 1 and LeMans, ultra high temperature ceramics, tungsten carbide tools sold by Sandvik and Kennametal, manufacturing of TRISO nuclear fuel, molds used to make Boeing 787 wings, SiC mirrors for satellites and castings for Lockheed and Sikorsky. Before DM, Fulop was a VC at NorthBridge, a fund with $3B in AUM. He led the Series A in Onshape, (acquired +$600M by PTC). MarkForged the first continuous fiber 3D printer (nasdaq: MKFG). Salsify, a leader in search (used by +1100 of the top commerce sites). Dyn (acquired +$600M by Oracle). Fulop continues to invest in startups including Hadrian, an automated manufacturer of space parts and top supplier to SpaceX and HighArc, the market leader in generative design software for construction. Fulop was also a co-founder of A123Systems in 2001 with MIT Prof. Yet Ming Chiang, a company instrumental in the developing the first long life high-power batteries and first to commercialize LFP (Lithium Iron Phosphate). LFP is now used in +30% of EVs globally and is the leading solution for grid storage. When he founded A123Systems in 2001 they had only made a small 10g sample of its new material at MIT and at the time of his departure in 2010 it had a public market capitalization of $1.5 billion, 1800 employees and shipped hundreds of millions of dollars. Fulop’s companies have generated +1000 patents and he is a co-inventor in 170 issued and pending. Fulop is a board member of Vicarious Surgical and former board member of https://endeavor.org/, the Electric Drive Transportation Association and Lytro. He’s built manufacturing lines in the USA, Mexico, Germany, Taiwan, South Korea and China. Fulop was a member of the Board of Governors of the World Economic Forum Advanced Manufacturing initiative and a founding member of the Global Lighthouse Network, an effort by the WEF to identify advanced factories and share best practices. Fulop is an avid pilot with 350 hours of piston and 1100 hours of turbine.

Carlos

Furlotti

Panel 8: Shark Bites: VCs Discuss Why They Do or Don't Invest in 3DP/AM

Carlos is a Principal at Exposition Ventures, a new VC investing in early-stage start-ups bringing frontier technologies to the manufacturing value chain. Prior to joining Exposition, he spent almost a decade at JPMorgan Chase’s Investment Bank in New York where he covered more than 100 clients in the industrial, automotive, transportation, aerospace and defense, chemicals, and oil and gas industries, amongst others. Carlos is also the co-founder of two stealth start-ups outside of the industrial space.

Richard

Garrity

Panel 1: The Polymer Toolbelt

Richard Garrity was appointed Chief Business Unit Officer in September, 2024. Previously, Garrity was Chief Industrial Business Officer since August, 2022, and President, Stratasys Americas, since August, 2016. Prior to that, Garrity was Senior Vice President and General Manager, Vertical Solutions, where he oversaw Stratasys’ product and service offerings in the aerospace/defense, automotive, medical, and dental vertical industries, as well as Stratasys Strategic Consulting. Garrity joined Stratasys in 2010, serving as Vice President and General Manager for its RedEye subsidiary, now part of Stratasys Direct Manufacturing.

Garrity has completed the Advanced Management Program at Harvard Business School and holds a B.S. in general management and marketing and an MBA from the University of Minnesota’s Carlson School of Management.

Harshil

Goel

Talk 3: Dyndrite

Inventor, engineer and mathematician, with degrees in pure mathematics and mechanical engineering from UC Berkeley, Harshil leads the Dyndrite team with a vision of how modern software will transform additive manufacturing.

Juan Mario

Gomez

Talk 4: XACT Metal

Juan Mario is founder and CEO of Xact Metal, a 3D printing company founded in 2017. Over the last six years, Juan Mario and Xact Metal have worked to establish a new price level for metal additive manufacturing, particularly in the powder-bed industry. Prior to Xact Metal, he worked at GE for over 27 years in various executive leadership, marketing, and engineering roles. He has worked in the aviation, energy, automotive and other industries. Juan Mario received a bachelor’s and a master’s degree in engineering from Boston University and an MBA from The University of Chicago Booth School of Business.

Lexi

Gormley

Panel 4: Policy for AM Healthcare

Lexi Gormley, PhD, is currently a Clinical Applications Specialist at Ricoh 3D for Healthcare. She guides medical professionals in designing patient-specific devices and developed a value survey to gather data on the clinical benefits of 3D medical models in healthcare. Lexi is also involved in assisting Ricoh’s randomized controlled clinical trial on utilizing patient-specific 3D printed models for preoperative planning of bony tumor removal procedures. Prior to working at Ricoh, she attended graduate school for biomedical engineering at Drexel University, focusing her thesis on the development of a novel approach for intraoperative breast cancer tumor margin assessment.

Paul

Gradl

Panel 2: The Industrialization of Additive for Aerospace

Paul Gradl is a principal engineer and subject matter expert at the NASA Marshall Space Flight Center (MSFC) in Huntsville, Alabama. Mr. Gradl serves as a Principal Investigator and leads several projects for additive manufacturing of liquid rocket engine engines and supports a variety of development and flight programs over the last 18 years. He authored and co-authored over 90 journal articles and conference papers; published a book under AIAA “Metal Additive Manufacturing for Propulsion Applications” in 2022; holds five patents; and regularly teaches courses in additive manufacturing. Gradl is the recipient of numerous NASA and industry awards and medals; an Associate Fellow of American Institute of Aeronautics and Astronautics (AIAA), member of SME, and serves on several additive manufacturing industry and government committees and as an advisor to industry. Gradl was named one of “The Most Influential Personalities of Additive Manufacturing in 2020” and the recipient of “Engineer of the Year” by AIAA in 2022.

Jeff

Graves

Panel 5: CEO Roundtable

Dr. Jeffrey Graves is President and CEO of 3D Systems. He joined the company in May 2020.

Prior to joining 3D Systems, from 2012 to May 2020, he served as CEO, President and Director of MTS Systems Corporation, a global supplier of test, simulation, and measurement systems. From 2005 until 2012, he served as President and CEO of C&D Technologies, Inc. He also held leadership roles with Kemet Corporation as Chief Operating Officer (2001-2003) and CEO (2003 to 2005). Previously he held a number of leadership and technical roles with GE, Rockwell Automation and Howmet Corporation.

Jeff currently serves on the Board of Directors of Hexcel Corporation.

He holds a bachelor’s degree in metallurgical engineering from Purdue University. He also holds a master’s degree and PhD in metallurgical engineering from the University of Wisconsin. He has been recognized with the distinguished alumni award from both universities. He is also a master black belt in six sigma.

Alfred

Griffin

Panel 7: A Founder’s Journey: Fundraising for Scaling Applied 3DP

Dr. Alfred C. Griffin III, DMD, PhD, MMSc is the Cofounder and CEO of LightForce. Dr. Griffin received his BS in Biochemistry from the University of Virginia and completed his DMD and PhD in Craniofacial Biology at the Medical University of South Carolina in 2014. He earned his Masters of Medical Research and Certificate in Orthodontics from the Harvard School of Dental Medicine in 2017. In addition to leading LightForce, Dr. Griffin practices in the Boston area and serves on faculty as a Lecturer in the Department of Developmental Biology at the Harvard School of Dental Medicine.

While an orthodontics resident at Harvard, Dr. Griffin co-founded LightForce in 2015 with the mission to revolutionize the specialty through advanced manufacturing and technology. After four years of extensive research and development, LightForce launched their first product to the Orthodontic market in 2020: the world’s first, and only, fully customized 3D printed bracket system and digital treatment software. Learn more at https://www.lf.co/

David

Hampel

Panel 5: Rebuilding the Industrial Base: Government and National Clusters

At Berlin Partner, the economic development agency of Berlin, David is responsible for the unit Manufacturing Industries. He focuses on technologies related to industries as lightweight solutions, robotics and Additive Manufacturing. AMBER as a cluster represents the 3D printing ecosystem of the capital region and is coordinated in David’s team. Before joining Berlin Partner, David worked internationally as a consultant in the pharmaceutical industry. He holds an MBA from Queensland University of Technology and studied business sciences at Helmut Schmidt University (University of the Armed Forces Hamburg).

Colin

Hautz

Panel 5: Metal AM Materials

Colin is the CEO of ArcelorMittal Powders, ArcelorMittal’s entry into additive manufacturing as a steel powder producer. With a broad background in metals and manufacturing, Colin’s focus is on promoting the advantages and potential of Steel Additive Manufacturing in industrial production.

Under his leadership, the company has launched the AdamIQTM brand of high-quality steel powders for various additive manufacturing processes, especially laser powder bed fusion (LPBF), binder jetting (BJ), and direct energy deposition (DED) systems. ArcelorMittal’s Global R&D have also identified significant opportunities for material development and printing optimisation which should benefit the series-production of end-use parts, either by delivering unique properties or driving down the costs of production.

A Mechanical Engineer from Trinity College Dublin, Colin’s career spans over three decades in manufacturing industries, two of which in steel, where he has held various leadership roles, most recently as Chief Marketing Officer of ArcelorMittal South Africa.

Greg

Hayes

Talk 3: AI in AM – Undervalued or Overhyped?

Dr. Gregory Hayes is a strategic technology development consultant with a strong background in high-end research and development, and a focus in materials science and engineering. Greg’s professional background began as a consulting materials scientist and technical program lead, working internationally in the health-tech, high-tech, and aerospace markets. Currently, Greg is senior vice president of applied technology at EOS North America, where he works to identify market needs and uses of Additive Manufacturing (AM) technology to develop products to fulfill those opportunities. Most recently as a program manager and director of new partnerships for AM at TNO, he concentrated on design and structure of research programs, acquisition of funding and partners, and general management. In 2016, he joined the JuntoHealth advisory board. Prior to that in 2014, Greg co-founded Complex Materials, a bespoke bioresorbable materials company with a focus on magnesium alloy stent tubing. Greg holds an ME degree from the University of Delaware; a Ph.D. in Materials Science from The Pennsylvania State University; and Start-up and Entrepreneurship certification from the Vlerick Business School in Belgium.

Ryan

Hayford

Panel 6: Polymer AM Materials

Ryan Hayford is a marketing and business development expert in the additive manufacturing industry with 15+ years of experience working with major hardware, software, materials, and service organizations. He manages his own B2B marketing consultancy and creative services firm, Hayford Consulting, that has collaborated with 25+ international businesses since 2019. Hayford is an accomplished writer that has been published in https://3dprint.com/ , Metal AM, Defense Weekly, AM Media, and more. He is a recognized speaker, moderator, panelist, and AM enthusiast.

Adam

Hecht

Talk 3: Automation & Robotic 3D Printing

Adam Hecht is the Co-Founder and Director of Additive Manufacturing at DIVE, Decibel, and 3DPets. Drawing on his Industrial Design background with a concentration in medical design from Thomas Jefferson University, Adam brings a holistic, design-oriented perspective to help organizations adopt cutting-edge 3D printing technologies. He oversees technology integration strategies, guides new customer projects, and manages content creation across all brands. A career highlight includes leading the 3DPets marketing campaign with Apple which was featured globally for the iPhone 14 Pro. Adam aims to advance sustainability and accessibility in manufacturing, bridging good design and advanced production solutions closer than ever before.

Arno

Held

Keynote: The drAMa Industry: (What) Have We Learned?

Panel 7: M&A and Capital Markets

Arno Held is Managing Partner of AM Ventures and specializes on the firm‘s ecosystem, as well as its global footprint and organizational growth. He started AM Ventures together with Johann Oberhofer in 2014. In total, Arno has more than 23 years of experience in industrial laser and manufacturing technologies and spent more than half of this time in the world of industrial 3D printing.

Since founding AM Ventures, Arno has been instrumental in building the AM Ventures team that has scouted more than 2,500 3D printing startups all over the world, conducted more than 35 rounds, built a €100m VC fund and today holds a portfolio of 17+ shareholdings in 6 countries on 3 continents.

Arno holds a diploma degree in industrial engineering and management from the University of Applied Sciences Karlsruhe (Germany) as well as an international executive MBA from the University of St. Gallen (Switzerland). Arno completed his studies in Shanghai, China and Cape Town, South Africa.

Jeff

Herman

Panel 7: A Founder’s Journey: Fundraising for Scaling Applied 3DP

Jeff Herman is the CEO and co-founder of Fabric8Labs. He founded the company with the goal of enabling high-volume manufacturing to access additive manufacturing capabilities through a new proprietary technology, Electrochemical Additive Manufacturing (ECAM). In 2017 Jeff was selected for the Forbes 30 under 30 for his part in developing Fabric8Labs’ patented electrochemical approach to metal additive manufacturing.

Karsten

Heuser

Panel 3: AM and Industrial-Scale Automation

Dr. Karsten Heuser is the VP of Additive Manufacturing as well as the Head of the core technology field Advanced Manufacturing & Circularity at Siemens AG. As AM community advocate, he is a member of VDMA AG Additive Manufacturing Advisory Board, a member of the Formnext Advisory Board as well as the Chairman of the Board of Trustees for the IAPT institute in Hamburg. He is engaged as thought leader worldwide for the industrialization of Additive Manufacturing community. Dr. Heuser has a Ph.D. in solid state physics from the University Augsburg as well as a Postgraduate Diploma in Advanced Management from ESMT.

Rob

Higby

Panel 3: Sustainability: Powering the Bottom Line

Rob Higby joined the company in April 2024 as Chief Executive Officer. Mr. Higby is responsible for leading the overall company strategy of delivering metal powder and powder services for the next generation advanced manufacturing industry. Rob is an experienced Aerospace & Defense and Space Executive focusing on Manufacturing, MRO, Commercial Growth, and Private Equity Investing.

Prior to Continuum, Rob served as Executive Partner and Head of AEA Investors Aerospace & Defense investment practice. During his time at AEA Investors, Rob led several investments for the firm and advised several other companies, namely, Velo3D Inc., where Rob served as Advisor to the Board of Directors and also interim Chief Commercial Officer during the beginning of the Covid period. Before AEA, Rob was CEO of TurbineAero, the world’s largest independent MRO provider of commercial and military auxiliary power units. Rob founded TurbineAero in early 2016 along with the Gores Group, a leading private equity firm based out of Los Angeles. Since its founding in 2016, TurbineAero has grown significantly and was listed as Arizona’s 24th-largest private company in 2018 and 2019. Prior to TurbineAero, Rob served as Executive Vice President of Sales and Marketing at StandardAero for several years, a $4B MRO focused on commercial and military aircraft engines, auxiliary power units, structures, and accessories. StandardAero was sold to Veritas Private Equity in 2015. Before that, Rob was Global Vice President of Sales and Marketing of GE Aviation’s Systems business.

Rob graduated from the Massachusetts Institute of Technology (MBA) and Duke University (BA). When not working with exciting next-generation companies positively disrupting their industries, Rob enjoys golfing, hiking, and skiing in Colorado with his wife Eva, and four children, Brayden, Matthew, Charlotte, and Lucy.

Chaw Sing

Ho

Panel 5: Rebuilding the Industrial Base: Government and National Clusters

Dr. Ho is the CEO of NAMIC, a national accelerator he co-founded that focuses on translational research to catalyse and scale industrial adoption of digital additive manufacturing technologies. In this role, he overseas Singapore’s development and implementation of additive manufacturing (AM) Research Innovation and Enterprise (RIE) strategies. Before joining the public sector, he spent 16 years at HP and Globalfoundries. Chaw Sing is an ASTM International board member and serves as an Adjunct Professor at NUS College of Design and Engineering. Active in the global AM community, he is the Chair’s Advisory Group Co-Convenor in ISO/TC 261 as well as co-chairs Singapore’s AM Standards Technical Committee. He is an advisor to startups and public R&D organizations including the Campus for Research Excellence and Technological Enterprise under the National Research Foundation and Singapore Maritime Institute, among others. Chaw Sing holds several U.S. and internationally issued patents. An INSEAD alumnus, he earned his doctorate and undergraduate degrees in Electrical and Computer Engineering from NUS.

Debbie

Holton

Panel 1: AM for Mobility

Debbie Holton is a business development, industry engagement, and marketplace expert with a proven track record of growing revenue, impact, and results in the manufacturing technology space. As Principal at Converge Consulting Group, she helps companies win the race for digital advantage via strategy development, industry engagement, technology trends, creative business models and custom solutions.

She is known as a change agent who champions new projects and fosters an organizational climate that seeks and supports innovation. She has strong technical knowledge on industry needs and cultivates strong relationships with leaders of companies, industry groups, and government agencies where her input is sought out and respected.

Holton has previously served as President of Metrix, an ASME company – a revolutionary startup – pioneering virtual events and digital engagement in advanced technologies. She launched successful strategies, new products, M&A and partnerships as Managing Director of Industry Events at ASME and as Vice President of Events and Industry Strategy at the Society of Manufacturing Engineers (SME). She also served as the Acting Director of Technology Transition at America Makes.

She has been recognized as a Notable Woman in Manufacturing, an America Makes Ambassador, and a Top Influencer in 3D Printing.

She holds a Bachelor of Arts degree from the University of Michigan and a Master of Business Administration degree with Distinction from the University’s Ross School of Business.

Neil

Hopkinson

Panel 6: Polymer AM Materials

Professor Hopkinson spent 20 years in academia generating Intellectual Property that has been licensed widely. Neil’s High Speed Sintering patents, first filed in 2003, have generated £1Bn+ in revenues to licensees, with thousands of industrial grade machines sold globally. In 2005 he was Lead Editor of “Rapid Manufacturing” (Wiley UK) the world’s first book dedicated to the use of Additive Manufacturing/3D Printing technologies for the production of end-use parts. Neil left academia in 2016 to join Xaar plc as Director of 3D Printing where he formed a Joint Venture with Stratasys called Xaar 3D. In 2001 Xaar 3D was fully acquired by Stratasys, where Neil serves as Vice President for Additive Manufacturing Technology and is General Manager of the SAF Business.

Dayton

Horvath

Panel 4: Market Forecasts

Dayton leads market research, consulting, and data product development in new technologies at AMT. With an initial focus on additive manufacturing, Dayton is expanding AMT’s membership, thought leadership, and offerings in high growth manufacturing technologies. Dayton’s subject matter expertise extends to strategic investments and M&A in the advanced manufacturing and materials industries thanks to his experience as an investment banking Principal at NewCap Partners. Previously, Dayton founded and grew his independent consultancy, The Additive Executive, which provided strategic advice, market analysis, and technology scouting for corporate groups and startup clients. Prior to The Additive Executive, he led the Materials Design and Manufacturing coverage area at Lux Research, a strategic advisory and market research firm. Dayton graduated with a M.S. in Chemistry from the University of California, Santa Barbara and a B.S. in Chemistry from the University of Connecticut as a University Scholar and Honors Scholar.

Troy

Jensen

Panel 5: CEO Roundtable

Troy serves as a Senior Research Analyst with expertise in high-growth technology stocks. He has over two decades of equity research experience following sectors such as 3D printing, unmanned aircraft, robotics, optical components, networking equipment, and RFID. Before joining Lake Street, Troy was a Senior Research Analyst at Piper Sandler for 15 years. He also worked at ThinkEquity Partners and RBC Capital Markets. Prior to his career in equity research, he worked as a Futures and Options Administrator at Cargill and spent six years in the Navy. Troy earned a BA degree from the University of Minnesota – Carlson School of Management. He is a CFA charterholder.

Mingu

Kang

The Private Equity Perspective

Mingu is the Founder and CEO of ARIS Technology. ARIS Technology designs, develops, implements, and sustains turn-key robotic 3D scanning systems for industries such as Aerospace & Defense and Automotive. ARIS Technology also provides a software platform and data solutions for the end-to-end 3D data collection and analysis, making ARIS systems more intuitive and user-friendly. ARIS Technology incorporates the state-of-the-art techniques in human-robot collaboration, digital twinning, artificial intelligence (AI), and extended reality to broaden the adoption of robotic metrology and inspection even to low-volume / high-mix manufacturing and sustainment applications. Before founding ARIS Technology, Mingu worked at institutions such as Avondale Strategic Partners, Deloitte, Goldman Sachs, and Merrill Lynch.

Matt

Karesh

Panel 2: The Industrialization of Additive for Aerospace

Matt is the Director of Defense and Government Programs at Velo3D and specializes in working with DoD entities and suppliers to educate on Velo3D’s capabilities, collaborate on defense related programs, and ultimately usher applications from R&D through full production solutions. He started his career in backup power generation before moving to commercial aviation, where he worked on high-pressure turbine blade design. Matt started working with additive manufacturing in 2017, and he has experience with several disciplines, including laser powder bed fusion, electron beam melting, and binder jetting. Matt’s previous roles include both engineering and commercial responsibilities at GE Aviation, Caterpillar, and Velo3D. Matt is a ‘hell of an engineer’ and holds a mechanical engineering degree from the Georgia Institute of Technology.

Eugene

Kim

The Private Equity Perspective

Mr. Kim is a Vice President at AE Industrial and a member of AEI Ventures, the venture capital investment platform formed in partnership with The Boeing Company. Prior to joining AE Industrial in 2018, Mr. Kim was a Specialist in the Corporate Development group at The Boeing Company, where he focused on M&A and other strategic activities. Prior to Boeing, Mr. Kim was a member of Sandler O’Neill + Partners’ Investment Banking Group, where he focused on M&A and capital raising for financial institutions.

Alex

Kingsbury

Panel 7: M&A and Capital Markets

Dario

Komsic

Talk 1: Digital Inventory Services

Dario Komsic is the Head of Marketing at IMS Verbindungstechnik, where he has worked for the past seven years. Originally from Bosnia and Herzegowina and based in Germany, Dario has a passion for innovation and has played a key role in introducing 3D-printed fasteners to IMS. His leadership in business development and his drive to explore cutting-edge technologies have helped create new business models for the company, serving the automotive and other industries worldwide.

Matt

Kremenetsky

Panel 2: Agile Manufacturing: Decentralized and Intelligent

Matt Kremenetsky holds a BA in history from Rutgers University, where his studies were focused particularly on U.S. foreign policy in the twentieth-century, Kremenetsky is a journalist and market analyst who writes about 3D printing from a geopolitical perspective. As such, Kremenetsky’s work at 3DPrint.com places an emphasis on 3D printing’s incorporation into the supply chains for strategically critical sectors, including energy, electronics, and especially, defense. Kremenetsky was an early documenter of the ground-level implications of the manufacturing policies driving Bidenomics, and specializes in connecting the daily unfolding of 3D printing news to the increasingly volatile shifts of the global macro environment.

Mikkel

Kring

Panel 2: Agile Manufacturing: Decentralized and Intelligent

Mikkel Kring is the Chief Product Officer and Managing Director of Craftcloud and All3DP.com. Two platforms aiming to make 3D printing more accessible and impactful for businesses and individuals. Since entering the additive manufacturing industry in 2017, Mikkel has been focused on bridging the gap between complexity and simplicity for users looking to start with additive manufacturing.

All3DP.com serves as a trusted resource for newcomers and professionals in the 3D printing industry, offering in-depth guides, product reviews, and educational content to help users understand the possibilities of additive manufacturing. By simplifying complex topics and providing actionable insights, it attracts a wide range of users eager to explore 3D printing technologies.

Through Craftcloud, these users can seamlessly take the next step by accessing an intuitive marketplace that connects them with leading 3D printing service providers. Craftcloud makes it easy to upload designs, compare quotes, and start printing, removing barriers and empowering anyone to turn their ideas into reality with minimal effort. Together, All3DP.com and Craftcloud provide a complete solution for users to discover, learn, and utilize 3D printing privately and professionally.

With a background in engineering and experience in precision manufacturing, Mikkel brings technical expertise and strategic vision to the field of 3D printing. Under his leadership, Craftcloud and All3DP.com have become trusted platforms for unlocking the transformative potential of additive manufacturing, empowering users to innovate, create, and scale sustainable solutions.

Stewart

Lane

Panel 5: Rebuilding the Industrial Base: Government and National Clusters

Stewart Lane is the Head of Business Development – EMEA at Renishaw plc, a global engineering company with activity within the fields of AM, Industrial Metrology, Position Measurement and Healthcare. He joined Renishaw in 2000 and has since held various significant roles within the company, including senior international management positions. In 2012 he was appointed to the Boards of the UK’s Manufacturing Technology Association (MTA) and CECIMO, the European Association for the Machine Tool Industry and he chairs both Additive Manufacturing UK (AMUK) and The European Additive Manufacturing Committee on their behalf. A fluent French and Swedish speaker, he is passionate about manufacturing and its role in socio-economic cohesion and advancement.

Chris

Lehman

Panel 6: Bridging the Public-Private Gap

Chris Lehman is a seasoned leader with deep expertise in defense policy, industrial base strategy, and consulting. He most recently served as the Deputy Director of the Office of Strategic Capital at the Department of Defense, leading the development and implementation of first-of-its-kind financial tools for the Department of Defense to strengthen the industrial base and scale critical technologies for national security. Prior to this role, he was a Senior Manager at EY focusing on strategy and supply chain work for commercial and government clients.

Previously, Chris served as the Director of the Defense Production Act (DPA) Title III Program, managing an expansive portfolio of investments to enhance critical industrial base capabilities for national defense. Chris revitalized and significantly expanded the use of DPA authorities to strengthen supply chains in strategic sectors such as critical minerals, microelectronics, space, shipbuilding and kinetic capabilities. Chris also supported the nation’s response to the COVID-19 pandemic, working in coordination with the interagency, DoD leadership and industry to rapidly expand the domestic medical industrial base and help stabilize the defense industrial base during the national emergency. He also served as Chief of Staff to the Deputy Assistant Secretary of Defense for Industrial Policy, where he advised on trade policy, industrial base investments, and international engagement initiatives.

In addition to his government service, Chris has worked as a strategy consultant advising clients in the commercial aerospace, defense, and federal markets. Chris started his career as a Marine Officer on active duty and continues to serve as a Marine reservist. He is a founding member of the Marine Innovation Unit.

Chris holds a Bachelor’s degree in Political Science from Yale College and an MBA from Georgetown University’s McDonough School of Business.

Max

Lobovsky

Panel 5: CEO Roundtable

Eric

MacDonald

Panel 4: Applications

Eric MacDonald, Ph.D. is a professor of aerospace and mechanical engineering and Murchison Chair at the University of Texas at El Paso and serves as the Associate Dean of Research and Graduate Studies for the College of Engineering. Dr. MacDonald received his doctoral degree (2002) in Electrical and Computer Engineering from the University of Texas at Austin. He worked in industry for 12 years at IBM and Motorola and subsequently co-founded a start-up specializing in CAD software and the startup was acquired by a firm in Silicon Valley. Dr. MacDonald held faculty fellowships at NASA’s Jet Propulsion Laboratory, US Navy Research and was awarded a US State Department Fulbright Fellowship in South America. His research interests include 3D printed multi-functional applications and process monitoring in additive manufacturing with instrumentation and computer vision for improved quality and yield. As a co-founding editor of the Elsevier journal Additive Manufacturing, MacDonald has helped direct the academic journal to have highest impact factor among all manufacturing journals worldwide. He has recently been involved in the commissioning of a second partner journal, Additive Manufacturing Letters, upon which he serves as the Editor-in-Chief. Recent projects include 3D printing of structures such as nano satellites with structurally-embedded electronics – one of which was launched into Low Earth Orbit in 2013 and a replica of which was on display at the London Museum of Science. He has over 100 peer-reviewed publications, dozens of patents, one of which was licensed by Sony and Toshiba from IBM. He is a member of ASME, ASEE, senior member of IEEE and a registered Professional Engineer in the USA state of Texas.

Erin

Mastroni

Panel 1: Specialist Services

With over a decade at the helm of i3DMFG, Erin’s leadership has been characterized by driving innovation in Direct Metal Laser Sintering (DMLS) and sustainable business practices. i3DMFG focuses on developing 3D production manufacturing solutions that meet the rigorous demands of the aerospace & defense sectors. Leveraging her background in sustainable enterprise and client relationship management to foster partnerships, Erin started i3DMFG in 2003 to revolutionize production with cutting-edge technology while creating family-wage jobs in her community.

Francois

Minec

Panel 1: The Polymer Toolbelt

Francois Minec is Global Head of Polymers at HP’s Personalization and 3D Printing Business. In this role he is responsible for leading the polymer teams and the development of the portfolio.

Francois has over 22 years’ experience in business development of specialty chemicals and plastics. Prior to his current role at HP, Francois spent 10 years as the CEO of VELOX, a European distribution company for speciality plastics and chemicals. He was also the founder of Advanc3D Materials and was shareholder and President of Setup Performance, which specialised in developing and producing innovative 3D printing materials. Both companies were acquired by BASF in 2018 and Francois spent 3 years as CEO of BASF Forward AM, highlighting a wealth of experience and knowledge of the industry.

Francois holds a Master’s degree in Chemical Engineering as well as an M.Sc. in Polymer Science. He also holds an Executive MBA awarded from ESCP Europe. He has lived all over the world in France, Belgium, Canada, South Africa, Spain, Germany, Switzerland and the UK. He is a keen sportsman and is passionate about skiing, snowboarding, sailing and kitesurfing.

Satish

Mishra

Keynote: Growing Role of Assistive Technology in AM Strategies

Dr. Satish Mishra is Head of Global Programmes, ATScale, Global partnership on Assistive Technology in November 2023. Satish brings to this partnership over 25 years of experience on assistive technology, rehabilitation and disability inclusion in global public health at country, regional and global levels.

Previously, Satish was the Regional Technical Lead for the Disability, Assistive Technology, Rehabilitation, Palliative and Long-Term Care unit at the WHO Regional Office for Europe.

Satish Mishra is an Occupational therapist by training with a Diploma in Business Management from India, along with a Master’s in Public Health and Doctorate of Public Health from the United Kingdom. Over the course of his two and half decade career, Satish has worked to increase access to health care for people with disabilities; strengthen rehabilitation services and improve access to assistive products; and build the evidence base for disability, rehabilitation and assistive technology. Satish has worked in over seventy countries across the globe, including low- and middle- income countries, in both humanitarian and developmental contexts. His previous work focused on strengthening policies and service delivery for people in need of rehabilitation and assistive technology, including people with disabilities, older people, people with noncommunicable diseases, and people with various other health conditions. Satish has authored several publications on the topics of disability, rehabilitation and assistive technology.

Dimitrios

Mitskos

Talk 1: Digital Inventory Services

Dimitrios is an accomplished leader with extensive expertise in the automotive Industry, specializing in systems Integration, innovative solutions and emerging technologies. With a deep understanding of the complexities of automotive systems, Dimitrios excels at driving efficiency, innovation and seamless operations across diverse projects. Under Dimitrios’ leadership Wurth Canada is developing a digital Ecosystem that combines physical and digital Inventory to increase customers efficiency and productivity.

Michael

Molitch-Hou

Panel 1: Specialist Services

Editor-in-Chief of 3DPrint.com Michael Molitch-Hou has been covering the additive manufacturing industry day in and day out for the past decade. He worked his way up from senior writer at 3D Printing Industry to Editor before transitioning to engineering.com, where he oversaw the 3D Printing news division while covering emerging technologies in CAD and construction. Now, Michael is dedicated to ensuring that 3DPrint.com remains the leading source for actionable intelligence related to 3D printing technology and the larger AM industry.

Alex

Monino

Keynote: Accelerating Adoption of Additive Manufacturing Applications

Alex’s has more than 15 years of experience in different positions at HP, which have taken him through different business units and given him extensive experience in the industry and a deep understanding of 3D market. is a key player when it comes to advancing strategic priorities as to unlock new opportunities and accelerate the mass adoption of Advanced Manufacturing

In his role as SVP & GM, Personalization and 3D Printing at HP, Alex leads HP’s disruptive technology and commercialization strategy to transform industries through new products, services, and business models with an explicit focus on applying HP’s advanced 3D Printing technologies in new ways to drive solutions across large markets.

Alex holds and Engineering degree on Industrial Organization by Universitat Politècnica de Catalunya, as well as formal training in Marketing Strategy and Management from INSEAD, Harvard and Kellogg School of Mgmt.

Mark

Morrissette

The Private Equity Perspective

Mark Morrissette is a Managing Director at Stifel Financial and its subsidiary, North Atlantic Capital. Mark has been in the private equity industry since 1995. Prior to joining North Atlantic in 2000, he worked at Advent International in Boston, and in consulting at CSC Index in Cambridge, MA. He is currently the Treasurer and serves on the Board of Trustees at the Portland Museum of Art, and is on the Board at SailMaine, a community sailing program. He earned a BA from Dartmouth College and an MBA from Harvard Business School.

Jason

Murphy

Panel 1: Specialist Services

Jason Murphy is an award-winning plastics industry expert starting his career designing and building molds. After earning his Master Molder credentials, he used that knowledge to assist global companies establish world-class molding facilities in Europe, Asia and Latin America. Combining his moldmaking and processing expertise, he has led several large-scale injection molding facilities in the medical device and packaging industries. He has combined that experience along with his more than 26 years in metal additive manufacturing for tooling to establish Next Chapter Manufacturing as an additive tooling company that produces complete solutions for reducing cycle time, eliminating defects and innovative mold components. Jason is a speaker and contributor to Moldmaking Technology magazine to educate the moldmaking community about what is possible with additive manufacturing.

Naomi

Nathan

Panel 3: Enablers to Scale AM in Healthcare

Naomi is a trained medical doctor, public health/health systems and policy specialist. Her professional experiences are at the nexus of understanding and providing innovative solutions to global health system issues – in relation to governance, reform, and collaboration/strategic partnerships in healthcare systems. She has held various roles in European organizations, including with the Association of Schools of Public Health in the European Region (ASPHER), and the WHO Regional Office for Europe (WHO Europe). In her current role as Head of Medical with Mobility/Medical goes Additive e.v. (MGA), she promotes collaboration, builds bridges and strategic partnerships in medical/healthcare additive manufacturing (AM) for the joint development of innovative products, targeted know-how and knowledge transfer – with a focus on a user/patient-driven approach and policies to boost AM in healthcare.

Nils

Niemeyer

Panel 2: The Metal Toolbelt

Nils Niemeyer, General Manager at DMG MORI USA, possesses over 15 years of manufacturing experience. Prior roles span Production Strategy, Product Management, Sales, and Service in factories and regional organizations. His AM passion ignited as a Global Manufacturing Consultant at Siemens, where he explored AM’s versatile applications, recognizing its disruptive potential in design and supply chain resilience alongside traditional manufacturing methods.

Nils earned a Dipl.-Ing. (B.Sc and M.Sc equivalent) in Mechanical Engineering and Production Technology from RWTH Aachen University, cultivating precision machining technologies in research institutes like RWTH Aachen University’s Machine Tool Laboratory (WZL) and the Laboratory for Precision Machining (LMP) at University of Santa Catarina (UFSC), Brazil. He received an MBA at the University of Chicago’s Booth School of Business, enriching his technical background with entrepreneurship and finance acumen.

Niall

O’Dowd

Talk 2: Is the AM Industry Ready for Closed-Loop Control?

Niall O’Dowd is the Chief Executive Officer of Phase3D, a pioneering company dedicated to advancing quality assurance technologies in the additive manufacturing industry.

With over a decade of experience in structural health monitoring and quality control, Niall has been instrumental in driving the commercialization of Phase3D’s innovative Fringe Qualification system, which ensures ultra-high quality in metal additive manufacturing processes. Holding a Ph.D. in Structural Health Monitoring from the University of California, San Diego, Niall combines deep technical expertise with strategic leadership.

He is the principal investigator on several multi-year programs for additive manufacturing certification for the United States Air Force, NASA, and Department of Energy. Niall’s vision extends beyond quality assurance; he is committed to fostering innovation and sustainability within the manufacturing sector.

His ability to bridge the gap between cutting-edge technology and practical application has led to significant advancements in metal additive manufacturing, enabling industries to produce complex, high-performance parts with confidence.

Christian

Ochs

Panel 1: AM for Mobility

Since 2021, Mr. Ochs is leading Siemens Mobility’s global 3D printing activities, overseeing operations across 14 locations worldwide. His journey in additive manufacturing began at Robert Bosch GmbH, where from 2017 to 2021, he served as Senior Manager for small series production and prototype construction. During this period, he successfully established an Additive Manufacturing Center at the Nuremberg plant. From 2015 to 2017, Mr. Ochs spearheaded a cross-divisional project to develop an autonomous mobile robot system for intralogistics, now known as ActiveShuttle at Bosch Rexroth AG. Prior to this, he was an expert and team leader in manufacturing planning and process development within Bosch Rexroth AG. Mr. Ochs’ career commenced in 2010 with the Robert Bosch Group’s international Graduate Management Program “Manufacturing,” which took him to both Germany and China. His extensive experience and innovative approach make him a distinguished figure in the field of additive manufacturing.

Neal

Orringer

Panel 6: Bridging the Public-Private Gap